How hot is my product going to get when it is beamed? A great question to be sure, and one that can be surprisingly difficult to answer…

Electron beam irradiation is a really fast process and delivers a lot of dose quickly. Dose being energy means there is a temperature rise in the product.

Let’s look at the theoretical part first, as that is the easy part.

The equation is ∆????=1000 ???? ???? / ????

ΔT is the change in temperature in °C

D is the dose in kilogray (kGy) = 1 kJ/kg; this has to be converted to Gray (J/kg) for the units to cancel and is therefore multiplied by 1000.

c is the specific heat of the material absorbing dose in J/(kg°C)

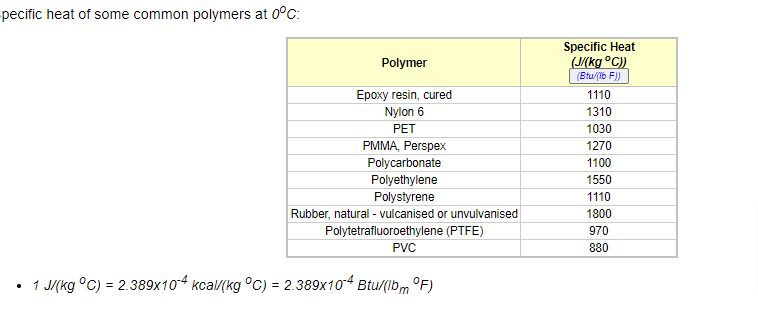

Now an example using data from engineeringtoolbox.com https://www.engineeringtoolbox.com/specific-heat-polymers-d_1862.html

For polycarbonate, a commonly sterilized polymer, using a 25 kGy dose, the math looks like:

1000 ???? 25 ???????????? / 1100 ????/(???????? °????)= 23°C

Another example is polyethylene that is commonly crosslinked, and using a 200 kGy dose, the math looks like:

1000 ???? 200 ???????????? / 1550 ????/(???????? °????)= 129°C

Wait! The melt point of polyethylene 135°C, how can polyethylene be dosed to crosslink it? Won’t it just melt? The answer is of course it would melt if it was dosed at 200 kGy in a single increment, therefore, when products are irradiated to “higher” dose levels, the dose is delivered incrementally or fractionally to the product. For example, we dose polyethylene parts at 20 kGy per pass for 10 passes. In between each pass is a delay of minutes before the next 20 kGy is delivered (which only takes a few seconds).

This time between passes allows for cooling, and a typical temperature that the parts may get to at 200 kGy may only be 75°C, a 50°C increase in temperature. How much cooling occurs and the ultimate temperature a product may reach is dependent on a number of factors, which makes it difficult to predict. It is also why we like to do qualification runs as close to what production settings will be to account for some of the factors beyond dose.

For sterilization applications, the maximum dose a product may receive within a case needs to be considered. With metals that may have a lower heat capacity, the temperature rise could be dramatic.

In special cases, different techniques of cold processing can be used involving refrigeration, freezing, or dry ice, but that is for another blog!