Crosslinking of polymers via electron beam irradiation (e-beam) is well known and the number of success stories involving it touch our daily lives in many ways – but more on that in a later blog. An important similar concept that might be a little less familiar to some is the process of chain branching.

What is chain branching? Chain branching occurs when a linear polymer is e-beamed with a minimal dose, resulting in side chains being formed, as shown in the figure below.

In contrast, crosslinked polymers contain a matrix of branches that connect polymer chains.

And why do you care about branching of polymers? So you can do the impossible! Because chain branching dramatically improves melt processability of linear polymers, you can down-gauge or form products in ways that otherwise wouldn’t be possible.

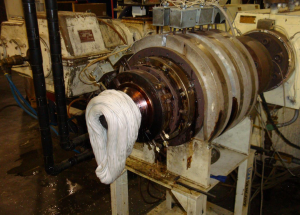

For example, E-BEAM ran a trial with a linear-low density polyethylene (LLDPE) for foam production. In this case, the actual resin pellets are e-beamed prior to the extrusion process. As a control the un-beamed linear polymer was run first and came out of the extruder a molten mess, after purging the branched LLDPE was run and came out as a foam.

Polymers where chain branching has been proven (in addition to LLDPE) are polypropylene, PVdF (polyvinylidene fluoride) and PLA (polylactic acid). Have more branching questions? Submit a question or give us a call!