To answer this question we have to discuss some of the practical considerations in the e-beam irradiation process. In general, the cost associated with the processing of cable is time—the time it takes to process a reel and the time it takes to splice or change over to the next reel.

The main aspects that affect the speed of the actual processing are: the dose required, the diameter of the cable, the flexibility of the construction, and the tackiness and toughness of the jacketing. We process faster a flexible cable that requires a lower dose and has a smaller diameter and a tough, smooth jacketing.

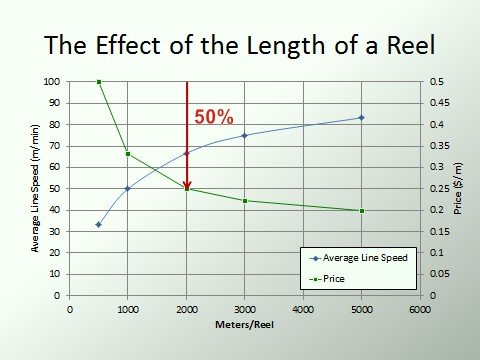

The second consideration is the time it takes to transition from one reel to the next. Completing one reel and splicing the next is a standard two-step process. So the more footage per reel, the lower the price, but there are a number of reasons the process has to stop longer, such as if there is a dose change, a major change in diameter or construction, or the whole processing run is completed. To minimize these effects, we evaluate and organize the reels in a given shipment to process in as efficient of a manner as possible. However, if there are fewer dose changes or fewer (substantial) diameter changes for a given processing run, this will reduce the time and therefore help reduce the cost of the processing.

We have a weight limit of 6,000 lbs. per reel. If the reels have the maximum length on them, this will reduce the number of changeovers (i.e. processing one 6,000 pound reel takes less time and is cheaper than processing two 3,000 pound reels). Also, if we receive the reels with the ends pre-stripped, this reduces the time we need to spend in preparing the reel before the next reel change (because the cable conductors must be electronically connected and grounded).

While some aspects cannot be controlled and are a function of the need for a particular reels or set of reels, there are usually ways in which the efficiency of the process can be improved, and therefore the cost reduced. Give us a call and let us see how we can process your cable efficiently!

www.ebeamservices.com • Ohio (513) 933-0031 • New Jersey (609) 655-7460