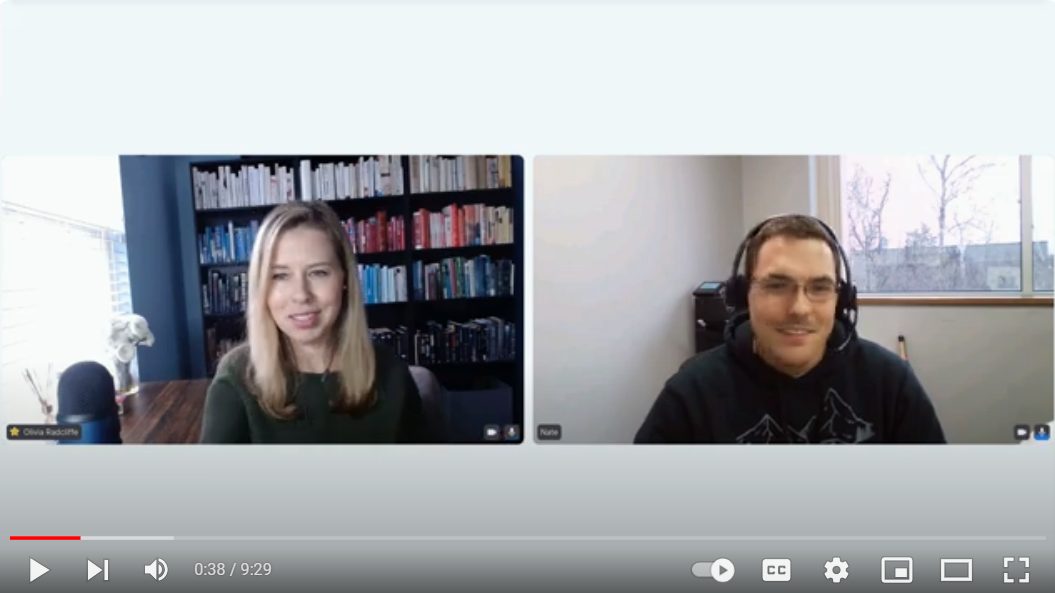

Sterilization is a critical process in various industries, ensuring the safety and quality of products. In the latest Q&A with Tech Services, Technical Services Coordinator Nate Hill delves into the process of sterilization at E-BEAM Services, highlighting its unique features, and discussing the implications for different industries.

The Process of Sterilization at E-BEAM Services

Receiving and Processing Products

At E-BEAM Services, the sterilization process begins with receiving and staging the products. Nate explains that they receive pallets of products, which are then depalletized and either processed in the carton, or unboxed and laid out on the conveyor, depending on the sterilization requirements. For sterilization purposes, the products are laid out on trays in a single-layer fashion to ensure accurate and consistent dosing. This method minimizes handling and allows for tight dose ranges.

Nate emphasizes that E-BEAM does not simply send entire skids or bins into the vault for processing, as some other sterilization methods might do. Instead, they carefully process each product individually to ensure the highest level of quality and accuracy. Processing each product individually allows for dry ice processing and cold processing at 4℃.

Electron Beam Exposure

Once the products are prepared on trays, they are exposed to the electron beam. Nate explains that the trays, containing the products, go around a track, passing under the beam multiple times. The beam delivers the required dose to sterilize the products, ensuring their safety and efficacy. The e-beam process is incredibly fast, with the dose being delivered in a matter of seconds, as opposed to other methods like gamma sterilization, which can take hours.

The quick turnaround time offered by E-BEAM is particularly beneficial for temperature-sensitive products that need to be processed and shipped quickly. This includes products that require refrigeration or freezing to maintain their quality. By delivering the dose rapidly, E-BEAM enables customers to meet their time-sensitive demands.

Handling Different Types of Products

E-BEAM Services can handle a wide range of products, including boxed products, cable and tubing, and sheet or film materials. E-BEAM Services is also licensed with the DEA to handle Class III Controlled Substances for sterilization. E-BEAM Services irradiates and handles materials that require special training and have strict regulations, like active viruses or radioactive materials. Nate mentions that they have recently started processing conduit, which is a mixture of cable processing and tubing. This expansion into new industries demonstrates E-BEAM Services’ commitment to meeting the evolving needs of their customers.

For cable and tubing processing, the products are unwound and sent into the vault, where they undergo multiple passes under the electron beam. The processed products are then rewound onto new reels, are repalletized, and are ready for shipment. This method ensures that the products receive the necessary dose to achieve proper crosslinking, while maintaining their integrity.

Sheet or film materials are also processed at E-BEAM. Similar to cable and tubing, the sheets are unrolled and sent into the vault for exposure to the electron beam. After the required number of passes, the sheets are rewound onto new cores and prepared for shipment. This process allows for efficient dosing of large sheets or films, catering to the needs of various industries.

Implications for Different Industries

The sterilization process at E-BEAM Services has significant implications for various industries. The quick turnaround time and accurate dosing make e-beam sterilization an attractive option for industries that require rapid processing and delivery of their products. This includes industries such as medical devices, pharmaceuticals, and cosmetics. E-BEAM Services regularly uses their accelerators for R&D and scholarly needs as well.

In the medical device industry, where sterility is crucial, E-BEAM’s process ensures that products are thoroughly sterilized without compromising their functionality. The fast turnaround time allows medical device manufacturers to meet tight deadlines and deliver their products to healthcare facilities promptly.

Similarly, in the pharmaceutical industry, e-beam sterilization offers a reliable and efficient method for ensuring the safety and efficacy of drugs and other pharmaceutical products.

In the cosmetics industry, where product safety and quality are paramount, e-beam decontamination provides a reliable method for ensuring the bioreduction of cosmetic products. The process is particularly beneficial for products that contain natural or organic ingredients that may be sensitive to traditional sterilization methods.

The process of sterilization at E-BEAM Services offers a comprehensive and efficient solution for various industries. With flexible processing configurations and the capability to deliver accurate dosing in a matter of seconds, E-BEAM helps ensure the safety and quality of a wide range of products. The ability to handle different types of products, including boxed products, cable and tubing, and sheet or film materials, makes E-BEAM Services a versatile irradiation provider, and its commitment to quality and customer satisfaction helps E-BEAM Services continue to be a leader in the field of irradiation service providers.