With a show of hands, how many of you wear makeup on a daily basis? I myself never leave home (and actually rarely even walk around home by myself) without mascara and some form of gloss or lipstick. And in today’s world, a lot of us care a lot about what goes into our makeup. But how many of us think about what it takes to create quality packaging for our favorite blushes and contouring palettes?

With a show of hands, how many of you wear makeup on a daily basis? I myself never leave home (and actually rarely even walk around home by myself) without mascara and some form of gloss or lipstick. And in today’s world, a lot of us care a lot about what goes into our makeup. But how many of us think about what it takes to create quality packaging for our favorite blushes and contouring palettes?

Today’s marketing throwback (Value-added process provides packaging with long-lasting barrier-resistant properties that extend shelf life of luxury cosmetics) will take a look at e-beam’s longstanding presence in the world of cosmetics–more specifically, the world of cosmetic packaging.

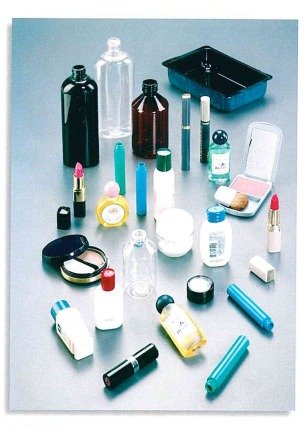

Packaging for cosmetics needs to not only keep oxygen out, but also needs to ensure the preservation of the cosmetic agents and fragrances within the packaging. Packaging made out of softer polymers can quickly absorb some of the key ingredients in the cosmetics, damaging the product before it reaches the end user. Electron beam crosslinking, though, can increase the stability and shelf life of cosmetic packaging, saving product without the need to obtain expensive, specially engineered materials.

After treatment, the newly-crosslinked packaging provides a moisture and oxygen protective barrier property, as well as improved resistance to the absorption of oils, petroleum, and other solvents. In addition to enhanced barrier properties, crosslinking provides additional performance enhancements that can include: improved tensile strength, impact resistance, resistance to slow crack growth, and reduced rapid crack propagation, not to mention the simultaneous sterilization that is occurring, as well.

And the entire process is safe, with no residuals and no additional chemicals needed! Just a few (well, a few million) electrons. In fact, the FDA views crosslinked plastics as unchanged and unadulterated as no physical change is made to either the resin or the finished package, and no special requirements are needed during the molding process.

So, get it, girl! Put on that extra coat of lipstick, E-BEAM’s got this.

And, as always, if you want to learn more, email me at ebeam@ebeamservices.com or give our friendly Tech Services reps a call at 513-933-0031.