In Part 2, we irradiated three samples of LLDPE with the electron beam to impart long chain branching and we achieved the improvement in melt tension we were looking for.

In Part 3, we irradiated one of the samples with a higher dose to produce LCB (long chain branched) LLDPE with a melt tension measurement of 14 cN.

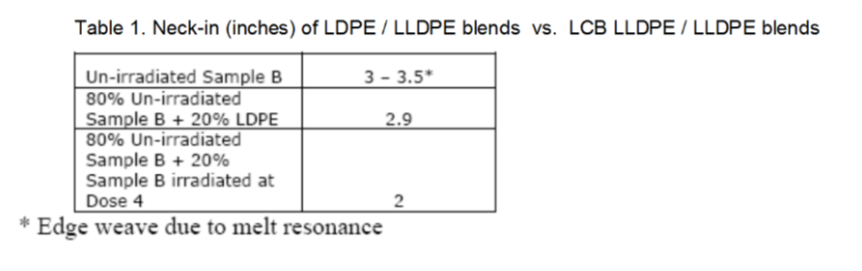

In the first demonstration, we extruded, as a control, 100% unirradiated LLDPE sample B into a slot die with a three stack chill roll take-away device. The neck-in was measured as an indication of the drawability of the material. Then we extruded a pellet/pellet blend of 20% LDPE and 80% unirradiated LLDPE. Finally we extruded a pellet/pellet blend of 20% LCB LLDPE and 80% unirradiated LLDPE sample B.

Not only did the 20% LCB LLDPE blend reduce neck-in significantly, it also eliminated the edge weave problem observed in the 100% unirradiated LLDPE.

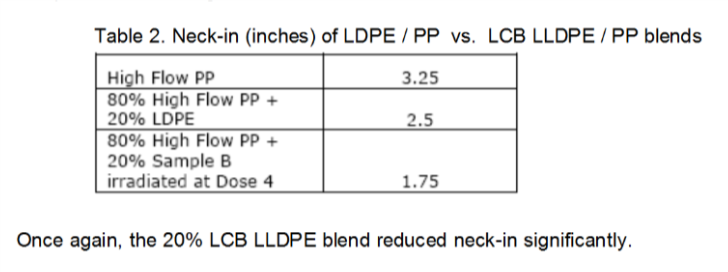

In a second demonstration, again, as a control, we extruded 100% high flow PP and measured neck-in as described earlier. Then we extruded a pellet/pellet blend of 20% LDPE and 80% high flow polypropylene (PP). Finally, we extruded a pellet/pellet blend of 20% LCB LLDPE sample B and 80% high flow PP.

Conclusion:

LCB LLDPE can be used as a melt strength modifier in both PE blends and PP blends, and at the same time offer the improved properties and higher heat resistance of the LLDPE.